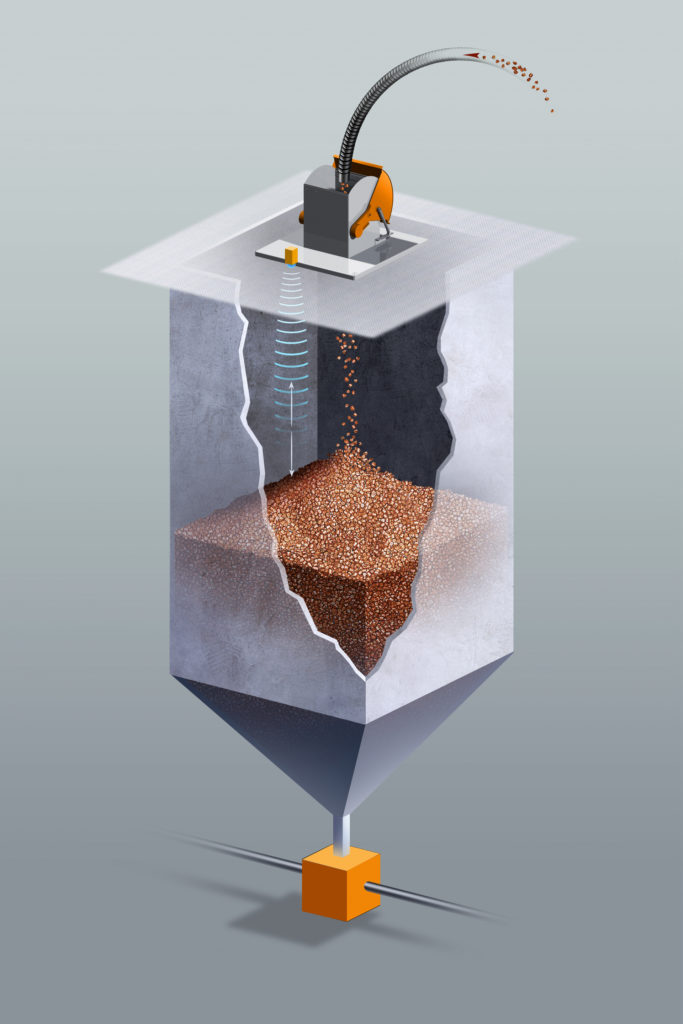

The Sobit System consists of remote controlled silo hatches and silo volume control scanners. The system is robust and functional, developed and tested in collaboration with the aquaculture industry, and has been in full-scale operation since 2016, in Norway.

Together with Sobit Silo Volume Control, it is easy to receive accurate figures on how much feed there is in each silo at all times, view the history of feed quantity used for all silos and receive digital reports from feed boat after filling, directly into the system.

The system contains:

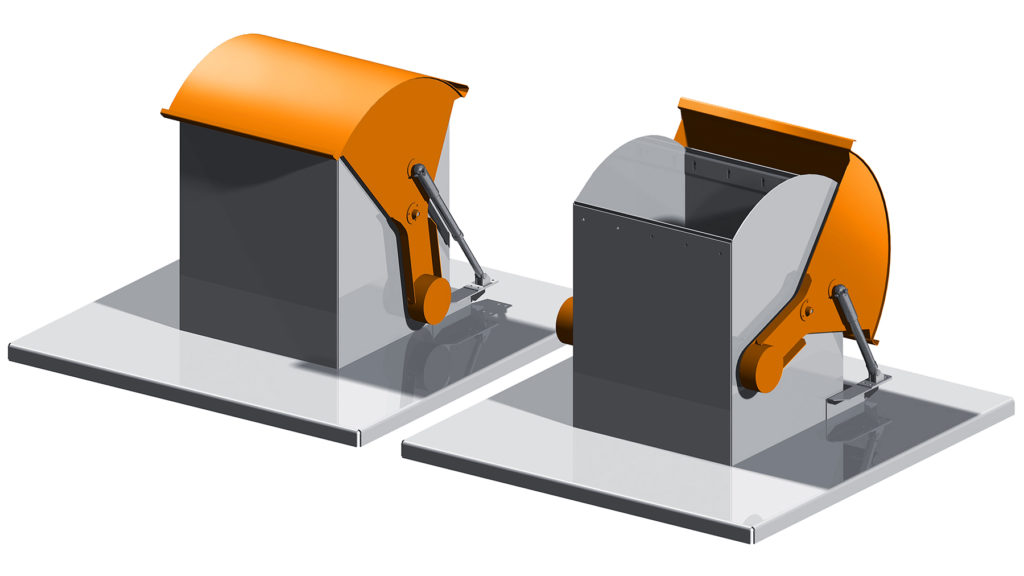

- Electronic/automatic opening and closing of the hatches.

- Full control of opening/closing og hatches, monitoring of exact feed level, temperature, humidity in each silo.

- Full control of silo content (in/outflow) with statistics function for benchmarking.

- Displays real-time silo activity.

- Filling can be carried out without the barge personnel present on the barge.

- Fully automatic control from devices that display all the necessary information, for example from a wireless handheld remote control (visual monitoring), or from a PC or wireless tablet (country/office) via the Internet (WIFI, 3G/4G or ICE networks) or the barge’s intranet.

- Camera module for visual monitoring (via the Internet or the barge’s intranet).

- The system works as stand-alone, regardless of generator. It is powered by two batteries that receive charging.

- Ventilation function – the hatches can be locked in an open position – from 10 – 100%.

Assembly and installation

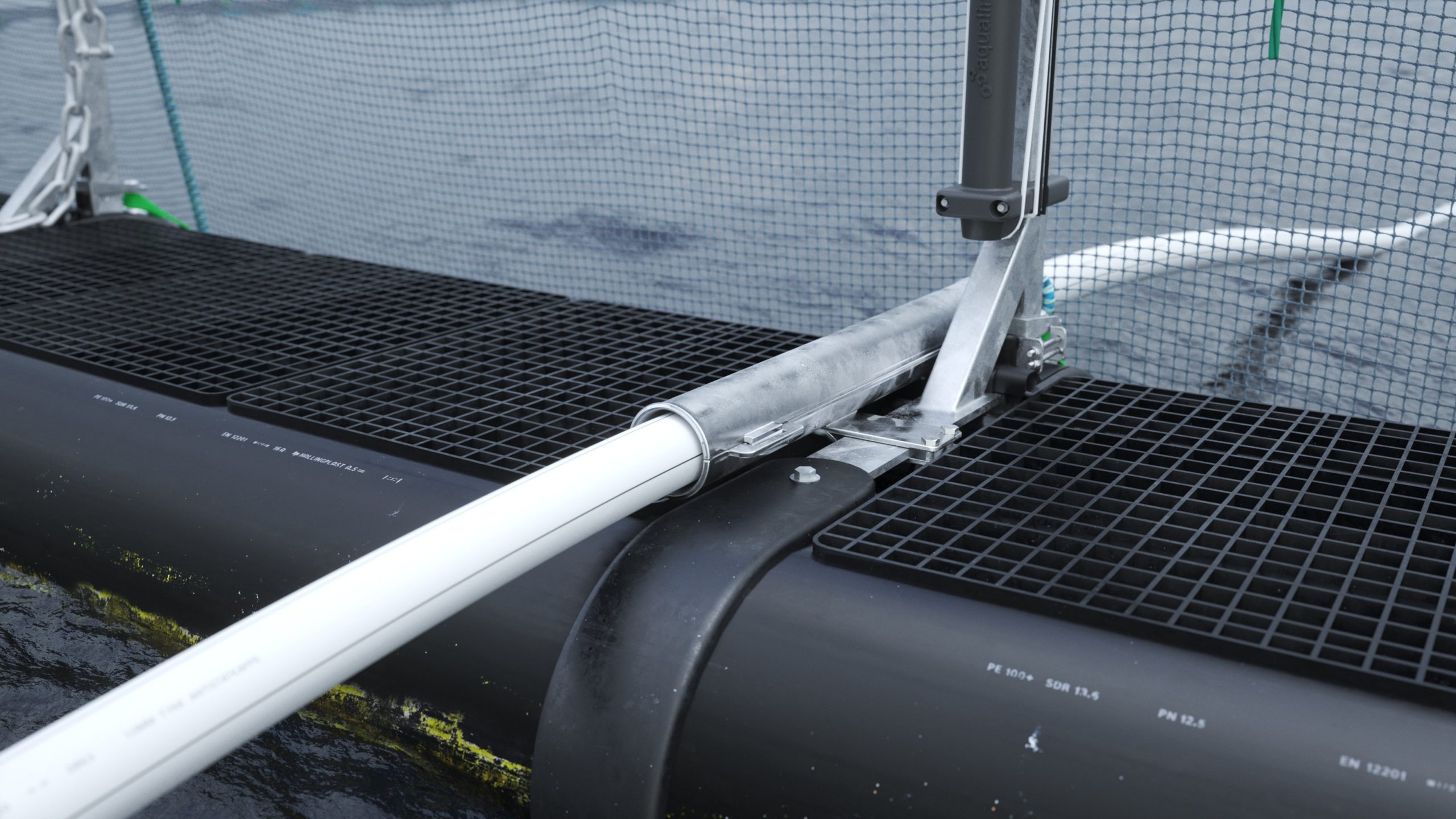

- The equipment can be adapted to all existing feed barges and silo solutions with only simple on-site remodelling.

- Old silo hatches are removed and replaced with new fully automatic Sobit silo hatches – while the barge is in full operation.

Installation of 8 silo hatches with associated infrastructure normally takes 3 days. - Efficient installation on site, no interruption to operations on the barge while assembly is in progress.

HSE

- No heavy lifting, handled using minimal physical force (by manual opening).

The hatch opening 90 cm above the deck eliminates the chance of falling into the silo. - The design prevents strong wind from affecting the position of the hatch in an open condition or during filling.

- Automatic reporting of any errors in the system

Technical

- The equipment is manufactured from high quality materials for use in the maritime environment.

- Emphasis is placed on good access for maintenance and service.

- Service kit with all necessary parts included in the delivery.