Infrastructure:

- High-speed CAT6a cables offering speeds of up to 10GB/s.

- Industrial network components supplied by Cisco.

- Industrial server and PLS components.

- Electrical cabinets with high quality components.

Capacity:

- 16 feed lines, with the option to expand further.

- Wide range of selector valves, augers and pipe dimensions available.

Software:

- User interface built on modern HTML5 technology.

- Advanced reporting, graphs and management capabilities.

- Open APIs for data exchange and process management.

- Supports multiple locations with full traceability of changes made.

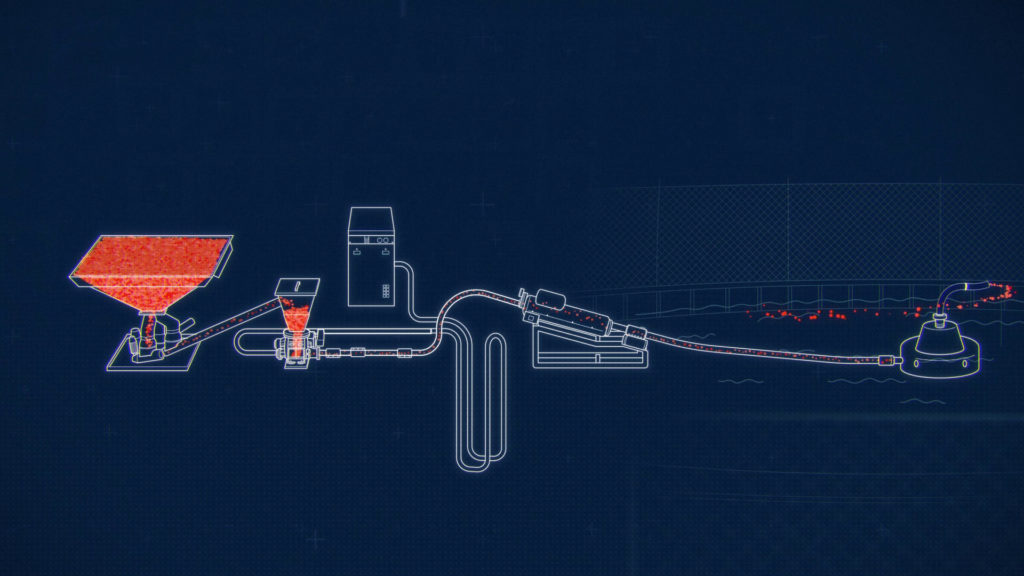

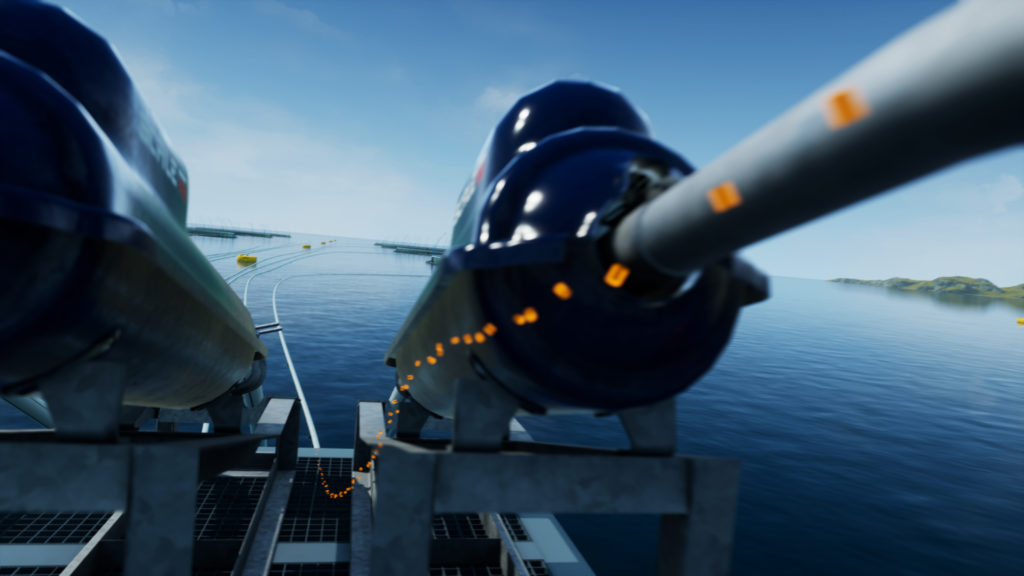

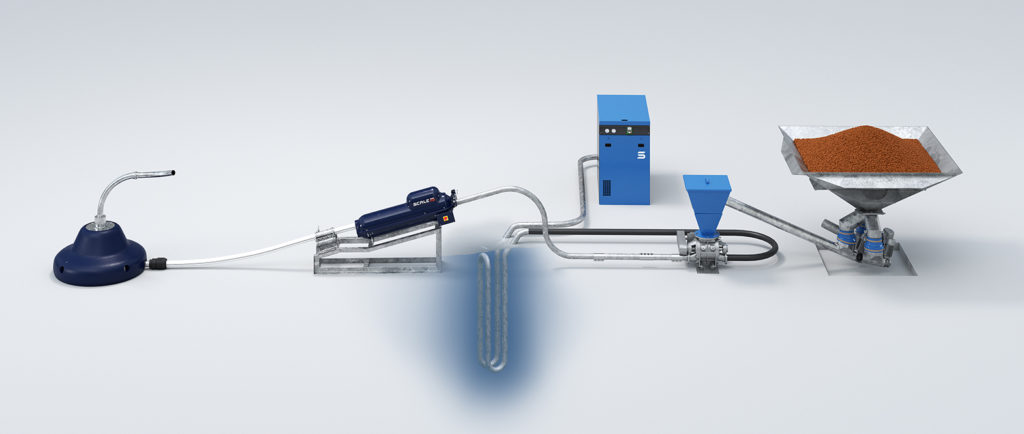

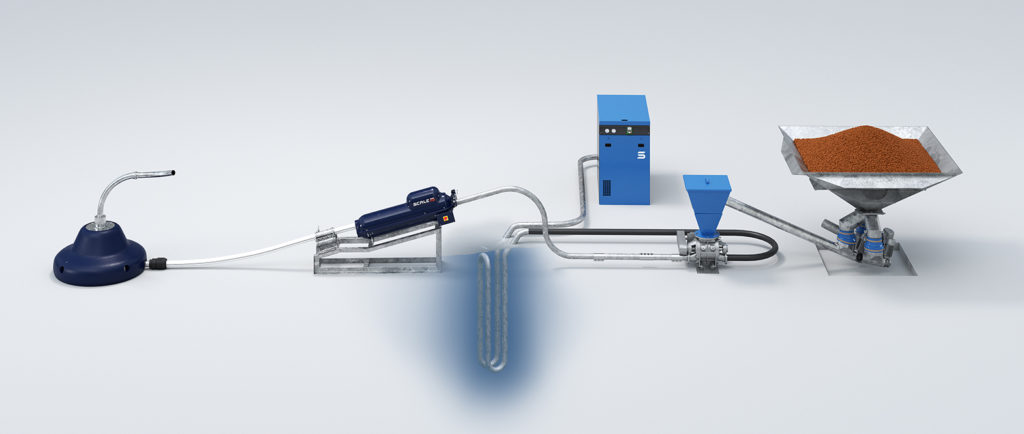

FeedStation Centralized Feeding System

ScaleAQ has more than 40 years of experience in developing and delivering world-leading centralized feeding systems to the global aquaculture industry. Thanks to years of product development, we have optimized the physical components to enable our customers to choose reliable, robust feeding systems for use in both landbased and seabased aquaculture. With the most user-friendly and future-proofed management software available on the market in the shape of FeedStation – ScaleAQ is the natural choice when you need a feeding system that you can rely on for many years to come.

Precision feeding

FeedStation feeding system deliver the right amount of feed, at the right time and in the most gentle way. Critical production parameters such as pressure, temperature and air speed are continuously monitored, and the system makes recommendations than ensure the operator has as much support as possible while carrying out feeding. Built-in tools for analyzing historical feeding profiles, and real-time display of your current profile, allow you to ensure that your company’s feeding strategy is adhered to at all times.

The world’s first open feeding system

At ScaleAQ, we are very proud to offer the world’s first feeding system featuring open and supported integration points for data sharing and process management. Do you have a sensor, a digital solution, or an algorithm that is designed to have an impact on the feeding process? FeedStation’s integration points (API) are standing by to receive the control signals! Well-structured and accessible data can provide increased understanding and insight. We want to help our customers become even better aquaculture operators, which is why we have made all the data that the feeding system produces openly available via the integration points.

Get involved in development

We help our customers to identify what can be reused from older facilities, so that you can easily and cost-effectively upgrade to FeedStation. Please contact us to join the technological shift – we can quickly supply you with a cost estimate for an upgrade to any type of system currently available on the market.

Quality

As our customer, you get one of the most user-friendly centralized feeding systems on the market – a robust and reliable system that gives you full control over the feeding process, regardless of your feeding strategy. We have installed over 900 centralized feeding systems at aquaculture facilities both on- and offshore. This makes us an expert in the field and a valuable partner when you are planning an update to your existing facility or want to discuss feeding solutions at a new site. The system handles the feed gently – from silo to fish. It features integrated cameras, sensors and remote control systems, and comes with built-in automatic integration to production management systems such as Mercatus Farmer. All components are carefully selected to provide you with easy and carefree maintenance, as well as long service intervals – resulting in lower costs to you. Our system consists of high quality industrial components. All parts of our feeding systems meet our quality requirements, meaning that we always deliver the most reliable systems.

Flexible

We customize systems to meet all your feeding needs, and our systems support all modern methods of feeding fish. The centralized feeding system can deliver pellets unscathed at a distance of up to 900 meters from the select valve, and simultaneously from two silos containing different pellet sizes.

Gentle feed treatment

We are all aware of the need to avoid minor damage to and crushing of feed. We supply systems with the same pipe dimensions throughout the system. We also avoid using joints in the distribution valve. There are no sharp edges, and we ensure that all angles in bends and pipes are optimized to prevent turbulence and in order to guarantee that the feed is whole when it reaches the fish.

Integration

Our feeding systems feature integrated external hardware such as cameras, environmental sensors and remote control systems to give you full control over your daily feeding routine on site. In addition, we also offer full integration with our software products for production control, planning and finance.

System maintenance

We offer system maintenance of mechanical components and software. Regular checks ensure stability and reliability in the long-term. Highly qualified personnel carry out detailed inspections and subsequently deliver comprehensive reports with recommended and preventive measures.

Capacities

| System | 50mm | Seasite 90mm |

|---|---|---|

| Feeding pipe size outer diameter | 50 | 90 |

| Feeding pipe size inner diameter | 42 | 76,1 |

| Feeding data (per line) | ||

| Pellet size | ||

| max | 12mm | 25mm |

| min | 0,5mm | 0,5mm |

| Kg per hour (max) | 360 kg | 4320 kg |

| Kg per hour (min) | 6 kg | 42 kg |

| Kg per minute(max) | 6 kg | 72 kg |

| Kg per minute(min) | 0,1 kg | 0,7 kg |

| Minimum dose | 16 gram | 90 gram |

| Transport lenghts | ||

| Max feed pipe length | 300 | 800 |

| Max feeding rate at max pipe length | 4 kg/min | 10 kg/min |

| Max feeding half length | 6 kg/min | 50 kg/min |

| Max feeding rate at short length | 6 kg/min | 72 kg/min |

| Power Consumption (max) | ||

| Feed blower(max) | 7,5 kW | 30 kW |

| Feed Blower (average) | 3,75 kW | 11 kW |

| Direct drive blower | ||

| Selector valve | 0,18 kW | 0,18 kW |

| Sluice | 0,37 kW | 0,37 kW |

| Auger | 0,37 kW | 1,1 kW |