The Norwegian Transparency Act was passed on June 10th 2022 to help businesses promote respect for basic human rights and decent working conditions in relation to the production of goods and services. This law enters into force on July 1st, 2022.

At ScaleAQ, we are positive about the rules and guidelines being introduced to ensure these values are safeguarded in our value chains. We are a key stakeholder in our industry, and it is our strategy to assume a leading position through a sustainable value chain and good working conditions, where safety, HSE, training and development are all central pillars of our work.

What does this mean for ScaleAQ?

The Norwegian Transparency Act requires ScaleAQ to carry out due diligence assessments and report on these assessments on a regular basis. This means, among other things, that we must examine and control risk in relation to negative impacts on human rights and decent working conditions throughout our supply chain.

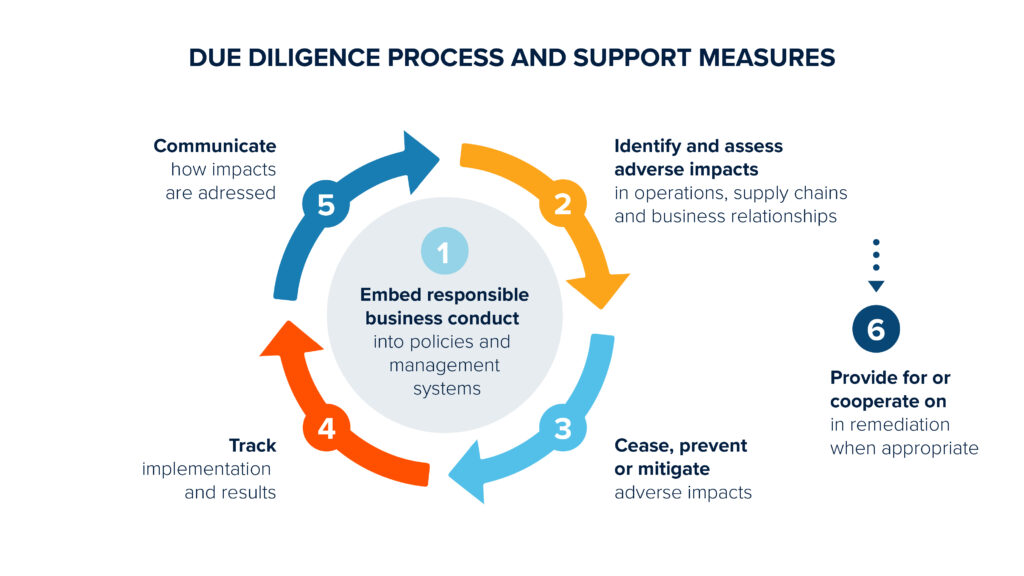

At ScaleAQ, we work in accordance with an overarching process which is as follows:

What are we doing in practice?

A requirement for compliance with human rights and decent working conditions has always been part of our procurement processes, and this work has been boosted even more in 2022.

Given our large supplier base, we carry out risk assessments on an ongoing basis to help us prioritize which companies we should focus on. We have therefore established a structured supplier follow-up program. All of our suppliers will be assessed at an overall level against four criteria:

- purchase value

- geography

- delivery risk

- priority product areas

Based on this assessment, selected suppliers will receive a comprehensive self-evaluation form on which they must document key areas such as their governance principles, HSEQ, sustainability work, and which processes they use in their own value chain.

Their responses will be evaluated and each individual supplier will be assigned a risk profile. They will be subject to customized follow-up and monitoring work on the basis of their risk profile, and this may require the submission of further documentation or the implementation of specific measures and more detailed monitoring.

This survey process is currently ongoing and we are working to put in place more system support for this. Additionally, work is underway on a toolbox for follow-up work and specific measures to prevent and limit negative consequences that may pose challenges to sustainability, human rights or decent working conditions.