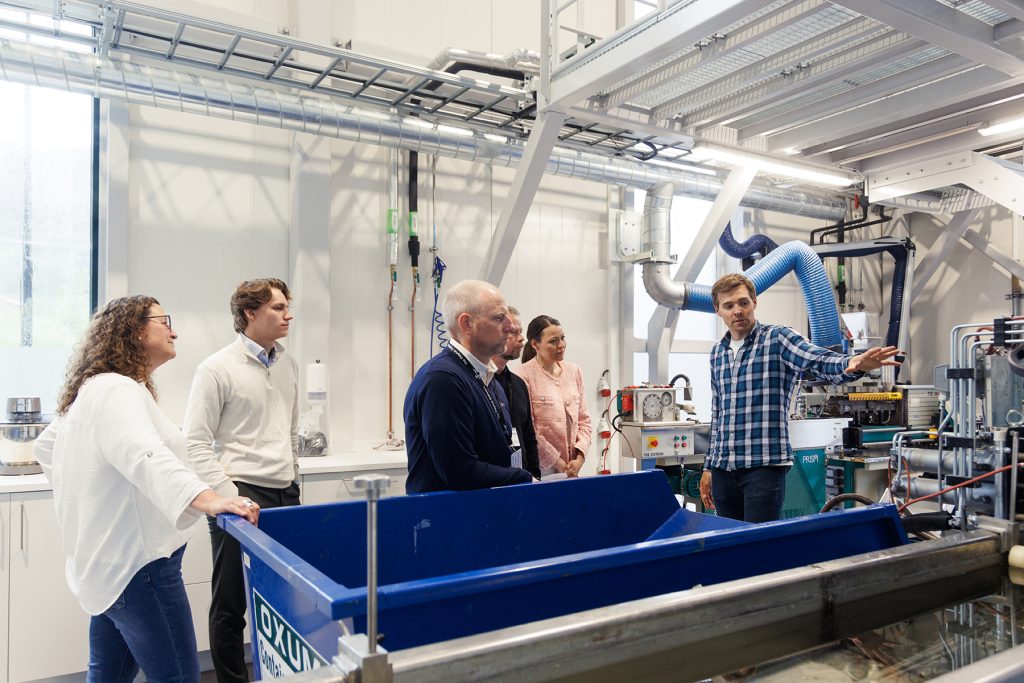

ScaleAQ aims to be a knowledge-based advisor to the aquaculture industry, and our products include documentation and follow-up that helps to ensure our customers can create added value. This is done through efficiency, reporting and increased information flow.

Good environmental, social and governance (ESG) principles are key to all activities undertaken by ScaleAQ, and we have tied our work to the UN’s Sustainable Development Goals. For the team at ScaleAQ, sustainability is about the future. We have to take care of the earth’s limited resources. We have to manage them in the best possible way without destroying opportunities for future generations.

The world is facing major challenges in securing sustainable food sources for a rapidly growing population. The demand for seafood is increasing globally, and aquaculture plays a central role in meeting this growth.

At ScaleAQ, we want to take our share of the responsibility in developing technology with animal welfare in focus. We contribute by developing good and relevant solutions in close collaboration with our customers and by documenting good animal welfare in our work. We are therefore committed to delivering technological solutions that safeguard animal welfare and to investing in R&D projects that promote the green transition both at ScaleAQ and for our customers.

We will work purposefully to ensure that fewer people are injured or become ill at work in ScaleAQ or within our value chain, both on the supplier and customer side. We will achieve this through culture, systems, risk management, and technology. Our goal is to make our deliveries the safest to use.

We are aware of our social responsibility and choose, both for ourselves and on behalf of others, to communicate sustainability in the industry in a clear and open manner through our podcast, ScaleAQ Pod, and other open channels.