Server room

On the barge we have added a small server room with spacious rack for ScaleAQ Server, UPS, Switches and Network CAT6A. There are planned pathways for cables to mast and to below deck for pen access. There will be reserved space for external equipment (radio, company IT infrastructure etc.)

Network infrastructure

The barges will be equipped with modern and future capable generic cabling with CAT6A technology for the barges system communication. The generic cabling can be added to implement company IT infrastructure on the barge. As well as wireless WAN inside and outside the barge. Furthermore ScaleAQ design the infrastructure to remote operation requirements.

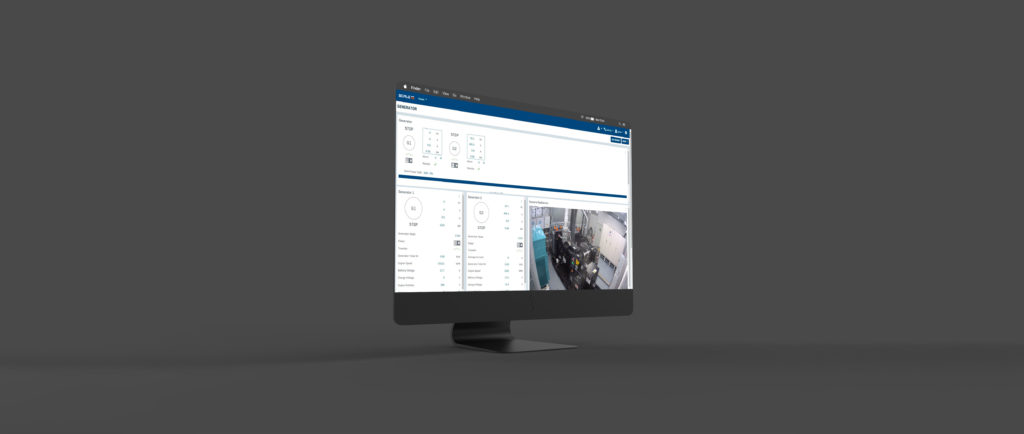

Barge Control

ScaleAQ can deliver a complete control system of the barge, the system is module based and different modules can be added by customers requirements. The control and surveillance system is integrated in the ScaleAQ software package delivered with the barge. All systems can be integrated into one user interface, available on the barge or on any other location via internet.

Available modules:

Ballast system

The Nova design can add ballast system to trim the barge when tank loads are causing some trim.

Door status

Doors with weather and water tight characteristics need to be closed to keep the barge safe should anything happen. When barges are remote operated or for extra safety the door status can be added. The system can warn if doors are left open over time.

Power and generator control

The generators can be controlled from the control room or remotely, with status and fault message history and warnings. Power logging and control and surveillance on loads can be used to prevent or warn of failures and unwanted stop.

Bilge control

The bilge and fire alarm can be added to the remote operation system, as well as testing and override of pumps. A diesel leakage system can be integrated, the system will detect and separate a diesel or oil leakage from a water leakage and not start the bilge until it is critical for the barges safety.

Tank status

A complete overview of the barges tanks capacity and filling level can be added to the operators information and planning.

Camera systems

The barges systems can be surveillanced by cameras in the silos, machine rooms, silo room or any other room requested by the user. The system will be integrated in the camera system for the dome and pen cameras in the Vision software.