The main advantage of a RAS facility is the formation of an aquatic environment that you – and not mother nature – can determine the quality of. To be able to have full control of that environment, the right choices have to be made at every stage, from choice of technology to the individual elements of the facility, and to how the facility will work as a whole.

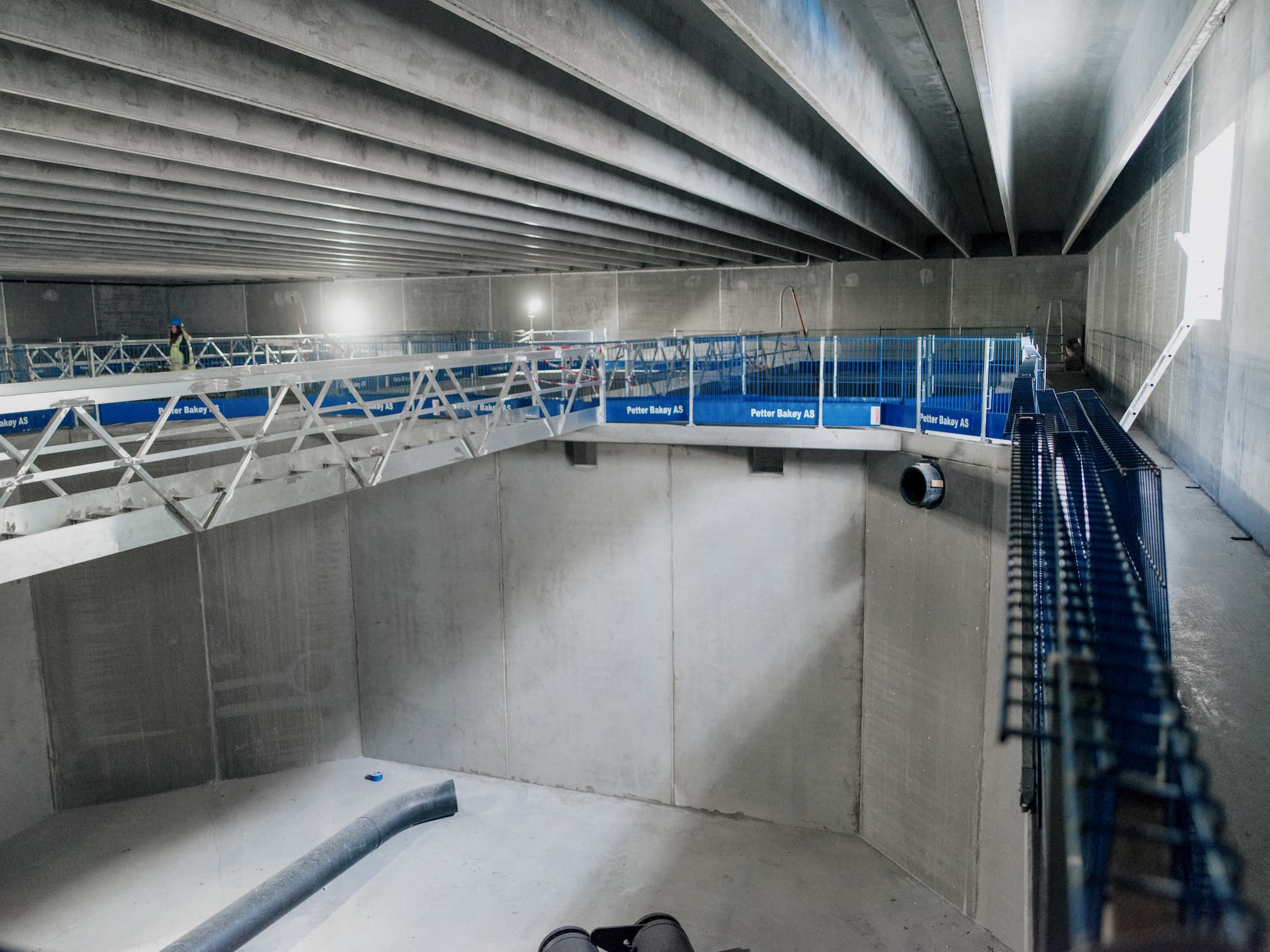

ScaleAQ Landbased builds turnkey facilities that guarantee optimal water quality for fish production. We believe that water quality is key, because clean water provides the best possible growing conditions for the fish.

“OptiFarm is our concept for a complete RAS facility,” says Senior Consultant and RAS expert, Astrid Buran Holan from ScaleAQ. “It’s designed for optimum fish health and growth. Every single component in the facility is carefully selected for the same purpose. The OptiFarm system gives efficient automatic cleaning of tanks, good water flow speed and optimal water quality.”

«ScaleAQ Landbased builds turnkey facilities that guarantee optimal water quality for fish production»

Removing particles

Particles such as fish faeces and uneaten feed quickly dissolve and pose a threat to water quality as they can affect the treatment process and increase the risk of sludge build-up. The latter is one of the RAS industry’s biggest problems, and often the reason why H2S accumulates.

To create and maintain optimal water quality, all particles in the water – even the smallest – have to be removed, and as quickly as possible.

“We want to provide the best possible solutions for fish farmers, and to make their lives easier. We believe in removing all the particles from the water – right down to the smallest – and as quickly as possible,” says Holan.

Doing so is easy if the right RAS technology is chosen, along with proper dimensioning and operation of the facility.

“If the health and welfare of the fish in the facility are poor, there is little chance of the facility making a profit,” Holan adds.

“Treating the water efficiently provides a high degree of fish welfare and production. An even distribution of fish throughout the full volume of the tank is also important to their health. And that can only be achieved if the water quality and hydrodynamics are correct in the whole tank.”

OptiTrap

OptiTrap is a system for efficient removal of particles in fish farming tanks. OptiTrap ensures that the biggest particles are quickly removed from the water. OptiTrap takes out up to 95 percent of the particles that could otherwise form sediment from the water.

“One of the major strengths of AquaOptima is our ability to remove sedimentary particles from the tank – feed that has not been eaten and faeces – in one process. That means that the side and central channels collect far fewer particles.”

Those same particles create unstable microbial conditions, as they are the ideal food for bacteria. There is also a major benefit to installing protein skimmers if ozone is introduced into the water loops to avoid sludge accumulation.

Correct feeding and regular cleaning of the pipes leading from OptiTrap are all that are needed to keep the system running – something that is a lot simpler than other methods that often require meticulous cleaning and maintenance.

“The alternative to RAS is a traditional flow-through facility, where you have large amounts of new water coming into your farm. That means that you can lose control of the water quality in the fish tanks. It also costs a lot to heat the water,” explains Holan.

OptiFlow

OptiFlow is a system for self-cleaning tanks. It consists of intake pipes, flow boosters and sensors to measure water flow in addition to the actual fish farming tank, OptiTank. The system is controlled in a manner that keeps the tank clean and the fish healthy.

“The hydraulic in the tank is important to provide the optimum environment for fish growth and health, and to ensure they live in conditions that do not cause them stress or discomfort. All the choices we take are designed to create the best possible growth conditions for the fish – from the colour of the tank, the size and internal surface, to the outlet and water intake,” stresses Holan.

ScaleAQ also ensures that the fish are kept in an environment they perceive as natural.

“We have worked with farms of all sizes and most breeds of farmed fish in the world – and we know how to achieve the perfect tank hydraulics for any type of facility.”

OptiTank

ScaleAQ uses octagonal tanks, because they provide optimal tank hydraulics.

“Maintaining optimal water quality in an octagonal tank is simple compared to the alternatives,” says Holan. Along with OptiFlow, octagonal tanks ensure good water quality, high oxygen levels and perfect flow throughout the tank.

Improved flow patterns

ScaleAQ has recently completed a CFD modelling research project, designed to show what happens with flow patterns in the tank, turbulence and rotation speed when tank diameter is increased in relation to the depth.

The results showed that a broader tank with the same volume gives better flow patterns in the tank. Fish in the tank thrive better with consistent, optimum hydrodynamics. Kinetic energy also shows that there is less turbulence in wider tanks, which in turn means better conditions for the fish in wide and shallow tanks. The project was a partnership with Overhalla Betongbygg, and supported by Innovation Norway.

OptiFarm also consists of a wide range of additional technology and smart solutions. Most of the preferred technology has been selected to provide the best possible environment for the fish. The RAS facility has to be designed to make it easy to produce fish in a safe, predictable manner – based on the conditions prevalent where the facility is to be built.

“Our solutions avoid having a whole chain of tanks on the same water source, but use sections consisting of four to six tanks. This way, if one section becomes infected, the spread is automatically limited. We also design the facilities with safe solutions for allowing personnel to pass from one section to another.”

All RAS facilities have to be built in a unique location with their own requirements for use of space, water supply and logistics, “Holan points out. “It’s important that such factors have to be dealt with according to long experience, a high level of expertise and in close consultation with the farmer.”

Facilities are dimensioned according to the conditions they are to exist in, which have to be realistic to achieve profitable operation and good fish health.

It is also important to feed correctly according to the dimensioning of the facility. It can be tempting to over-feed – but that can also create problems. If the facility is not dimensioned correctly, tank hydraulics can be affected, which can also mean poorer water quality and thus poorer fish welfare.

About ScaleAQ Landbased

ScaleAQ is a supplier of turnkey RAS facilities, and we can deliver turnkey projects of any size. Our world-leading position in aquaculture also enables us to deliver the latest in innovations from one of the world’s leading communities in aquaculture technology. Our staff includes biologists, fish farmers and engineers who have designed hundreds of RAS facilities.