Your Trusted Partner in Marine Engineering

Our goal is to provide the aquaculture industry with safe, sustainable, and cost-effective solutions that contribute to increased production and further development of the sector. We help our customers achieve this by offering:

- Tailored Design and Engineering: We develop pen structures, mooring systems, and components based on thorough analysis and simulations.

- Documentation and Certification: We ensure that all solutions comply with industry standards, including NYTEK23 and NS9415:2021.

- Testing and Quality Assurance: All products undergo rigorous testing to guarantee operational reliability under demanding conditions.

- Innovation and Concept Development: We invest in research and development to create innovative solutions that meet future needs.

- Turnkey Deliveries and Project Management: We take full responsibility for the entire process—from analysis and design to production, installation, and follow-up.

Collaboration with Customers, Suppliers, and Authorities

To deliver the best solutions for the aquaculture industry, we work closely with:

- Customers: We tailor our solutions to meet specific customer requirements, ensuring optimal performance and longevity.

- Suppliers: We collaborate with reputable partners to guarantee the highest quality in all components and systems.

- Authorities and Certification Bodies: We adhere to all applicable regulations and standards to ensure compliance with industry requirements.

Our Organization

To strengthen our ability to deliver comprehensive solutions, we have consolidated expertise across disciplines, including structural engineering, hydrodynamics, design, mooring, concept development, and documentation, into a single unit: Marine Engineering.

The department is led by:

- Håkon Tønne, Director of Marine Engineering

- Kasper Wåsjø, Head of Mooring

- Lars Andreas Larsen, Head of Pens and Nets

- Magnus Theodorsen, Head of Development New Concepts

- Geir Håvard Espnes, Technical Compliance Manager

Analysis

To determine the optimal solutions for mooring, net pens, and floating collars, we conduct advanced site-specific analyses and assessments. Our team of highly qualified specialists uses state-of-the-art analytical tools to ensure all components are dimensioned according to industry standards.

We combine our customers’ practical experience with advanced site classification and simulations. Our data models allow us to simulate real-world conditions at a site, including extreme weather scenarios. By integrating current and wave data, we can accurately calculate the forces acting on mooring systems and pen structures, ensuring they remain within the safety margins defined by the NS9415 standard.

For additional quality assurance, we conduct a final assessment of the deployed mooring system. We analyze all relevant data and provide a detailed report documenting the system’s performance and safety.

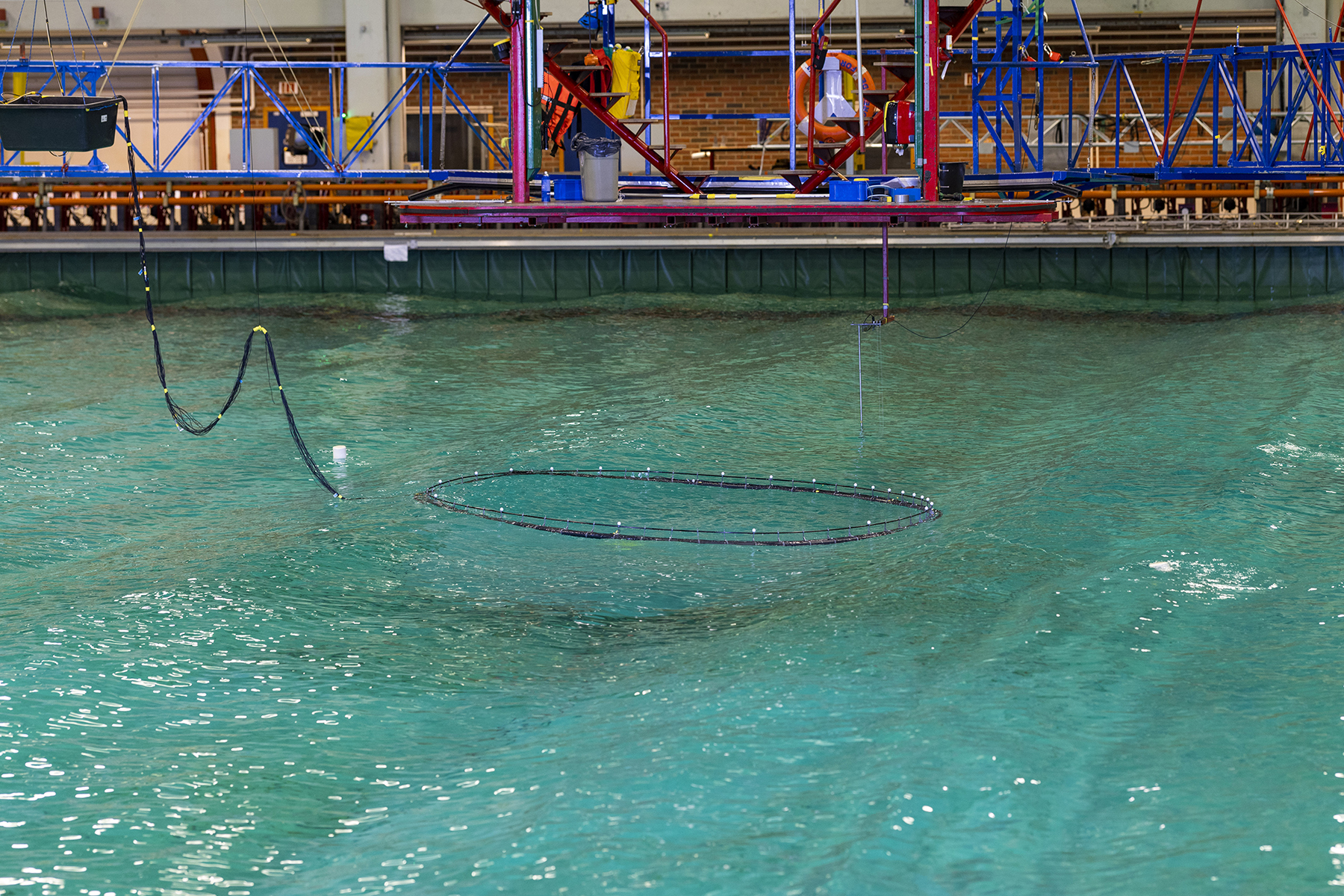

Testing

To ensure our products withstand extreme loads, we conduct extensive testing of both individual components and complete structures. Our testing process combines theoretical calculations with practical stress tests to validate material strength, design integrity, and functionality.

We utilize high-capacity winches to simulate real-world loads on floating collars and mooring systems. By subjecting equipment to controlled, extreme stresses, we can identify potential weaknesses and optimize solutions before deployment.

Testing is carried out in close collaboration with our customers to ensure that each solution meets specific operational requirements. Through systematic testing and result analysis, we contribute to the development of even more robust and reliable products for the aquaculture industry.