Nylon

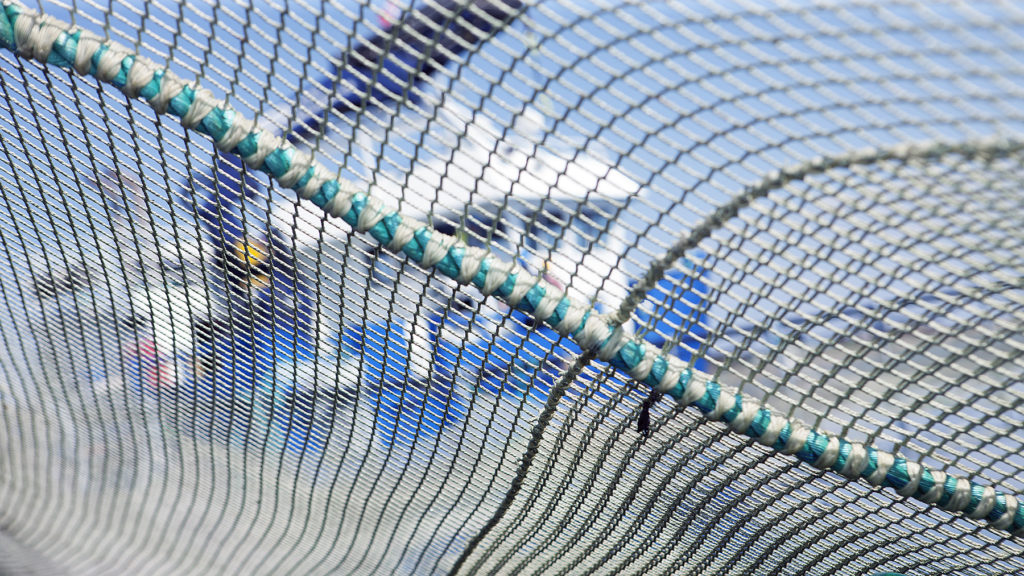

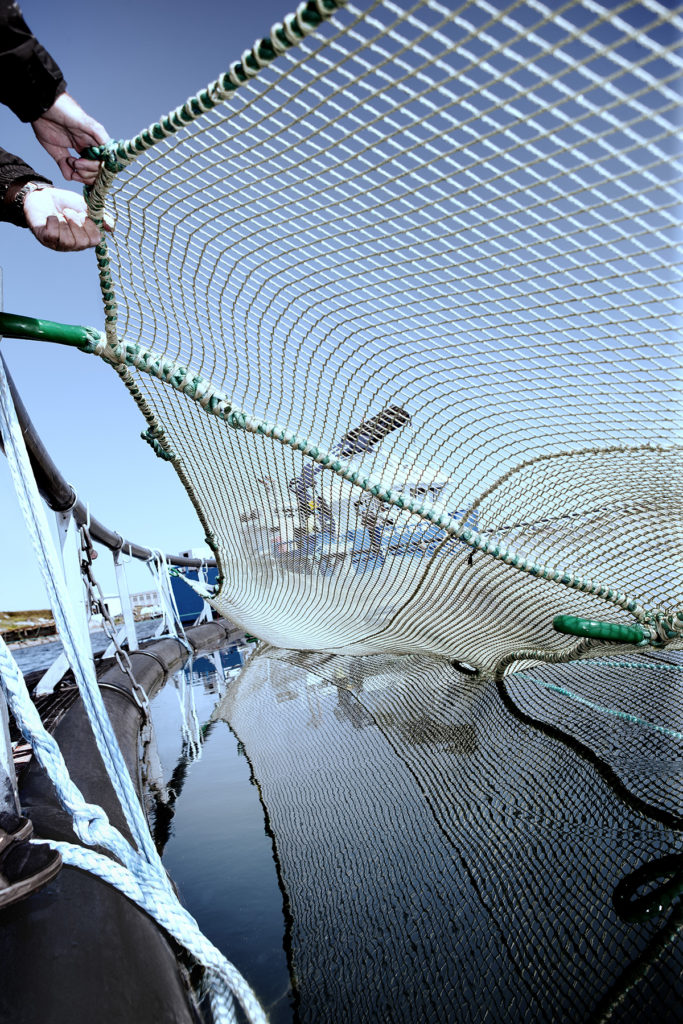

- The most commonly used material for bag nets in aquaculture

- Cost-effective

- Easy to work with and repair

- Treated with either antifouling or coating in order to reduce fouling and ensure more straightforward maintenance/rinsing

- Supplied both as a nodal line and non-nodal

- Considered the ‘standard netting’ in Norway and used by most customers at present

Polyester

- A good deal heavier than nylon

- Good against UV

- Good form stability

- Less shrinkage than nylon

- Treated with either antifouling or coating in order to reduce fouling and ensure more straightforward maintenance/rinsing

- Supplied both as a nodal line and non-nodal

- Resistant to wear

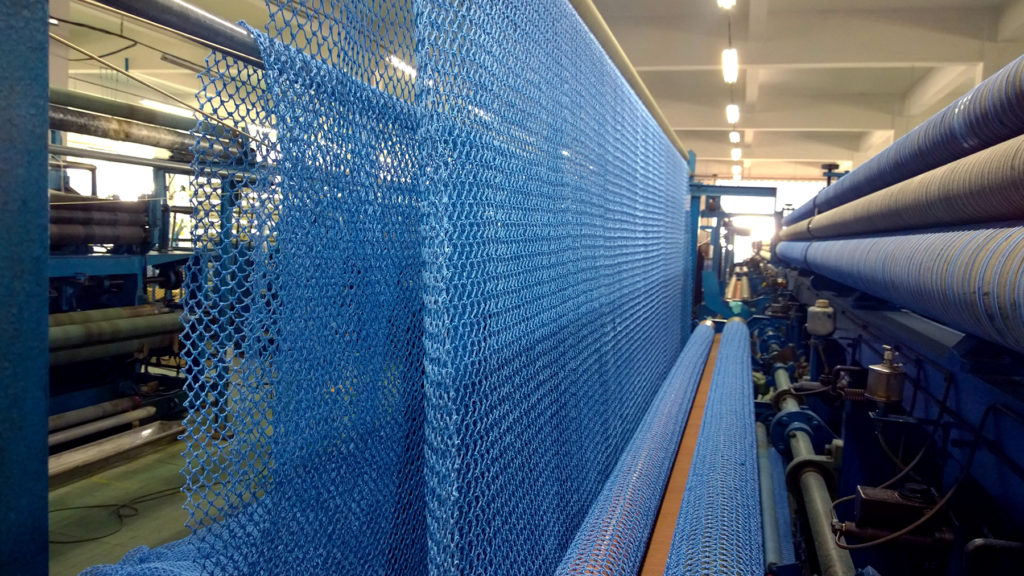

HDPE

HDPE have been tested under extreme stresses and demonstrates excellent properties in terms of fracture strength and wear. Third-party tests document the superior strength of HDPE.

- Extremely durable

- Withstands high frequency of washing

- Environmentally friendly – no antifouling

- Long service life and low service costs

- Reduced escape risk

- Designed to ensure better sinkability

- Better water flow than traditional nets, which provides a better environment in the note

- Less deformation and inflation of the netting

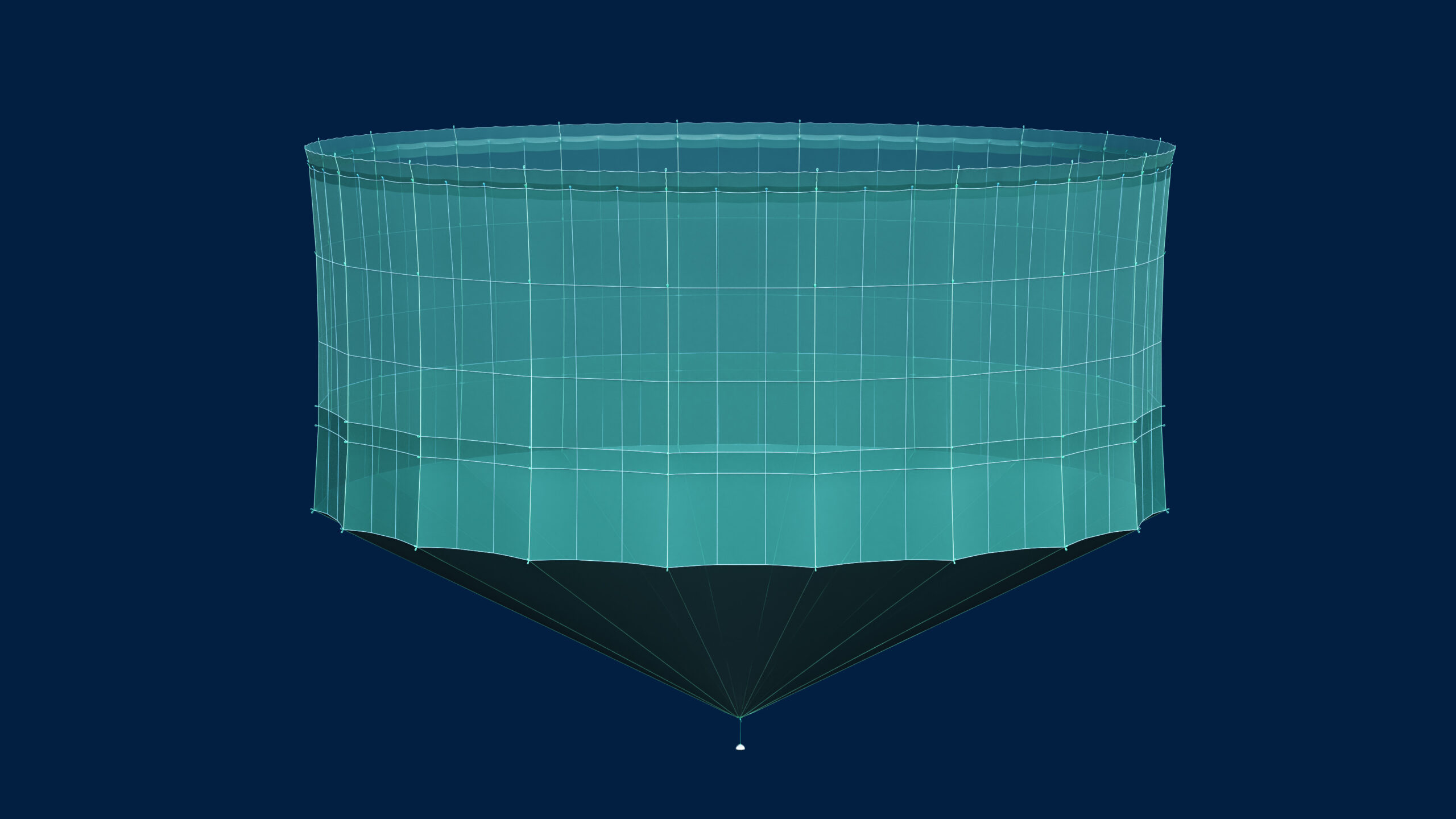

UHMWPE

Stronger netting, which has very good properties with regard to breaking strength and wear. It has undergone rigorous testing, withstanding high-stress conditions and repeated net cleaning, surpassing traditional netting in both wear resistance and breaking strength. Improved water flow provides a better environment for the fish.

- Extremely durable

- Withstands high frequency of washing

- Environmentally friendly – no antifouling

- Long service life and low service costs

- Reduced escape risk

- Designed to ensure better sinkability

- Better water flow than traditional nets, which provides a better environment in the note

- Less deformation and inflation of the netting