Easy to set up – easy to customize

- Can be installed on most boats.

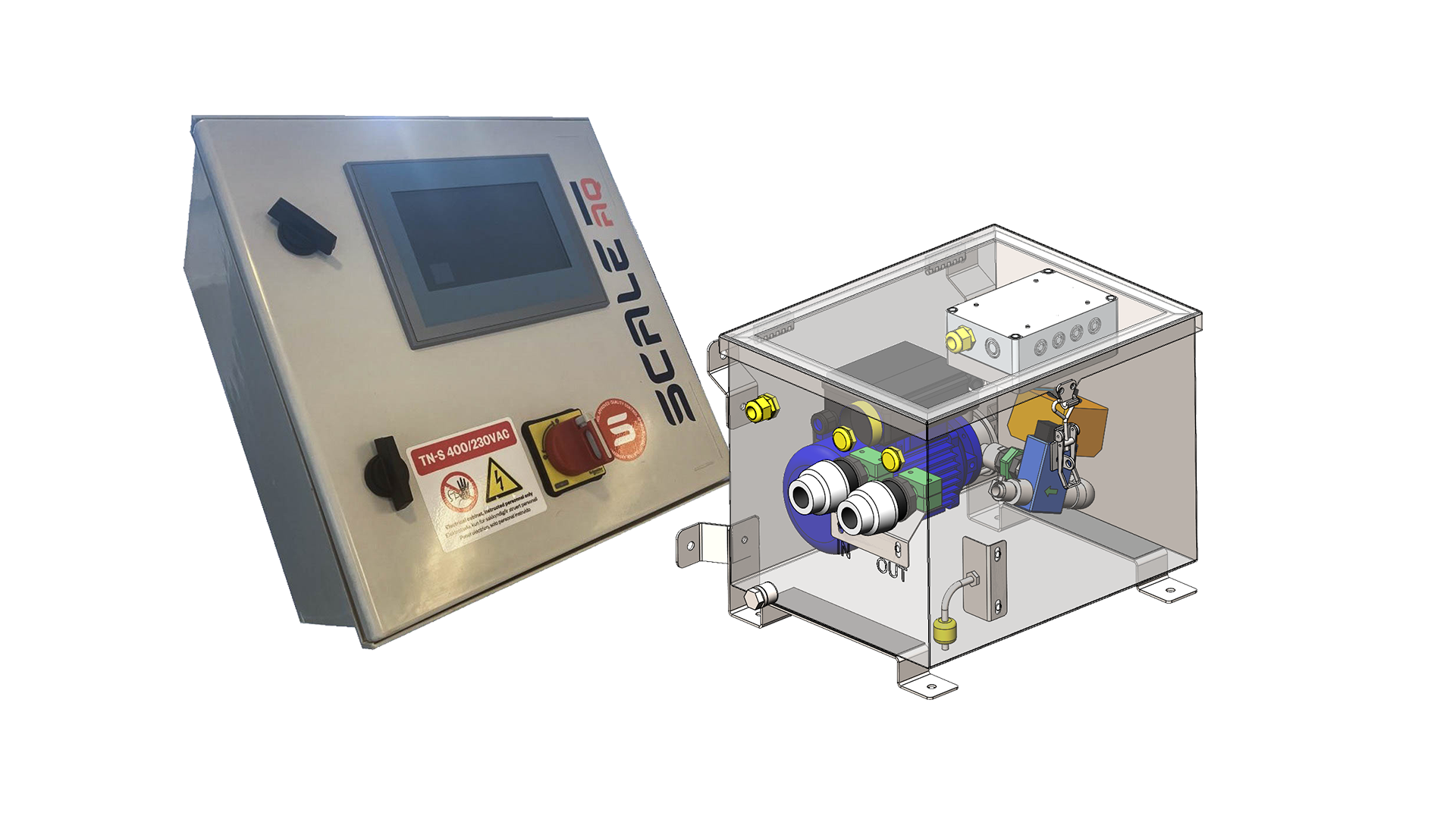

- Plug and play solution that utilizes energy from the hydraulics, which the workboat already has today. Requires little capacity; four liters per minute.

- Connects to an external compressor. Minimum air requirement for CleanPump is 3,5 m3/min.

- Controlled with a remote control connected to the crane’s hydraulics.

- Supplied with hydraulic operation, but we also have solutions for electric operation.

- Comes standard with a 50-meter suction hose. Feel free to ask us if you want a longer hose.

- Efficient filter box with good drainage.

Reduced risk of fish escape

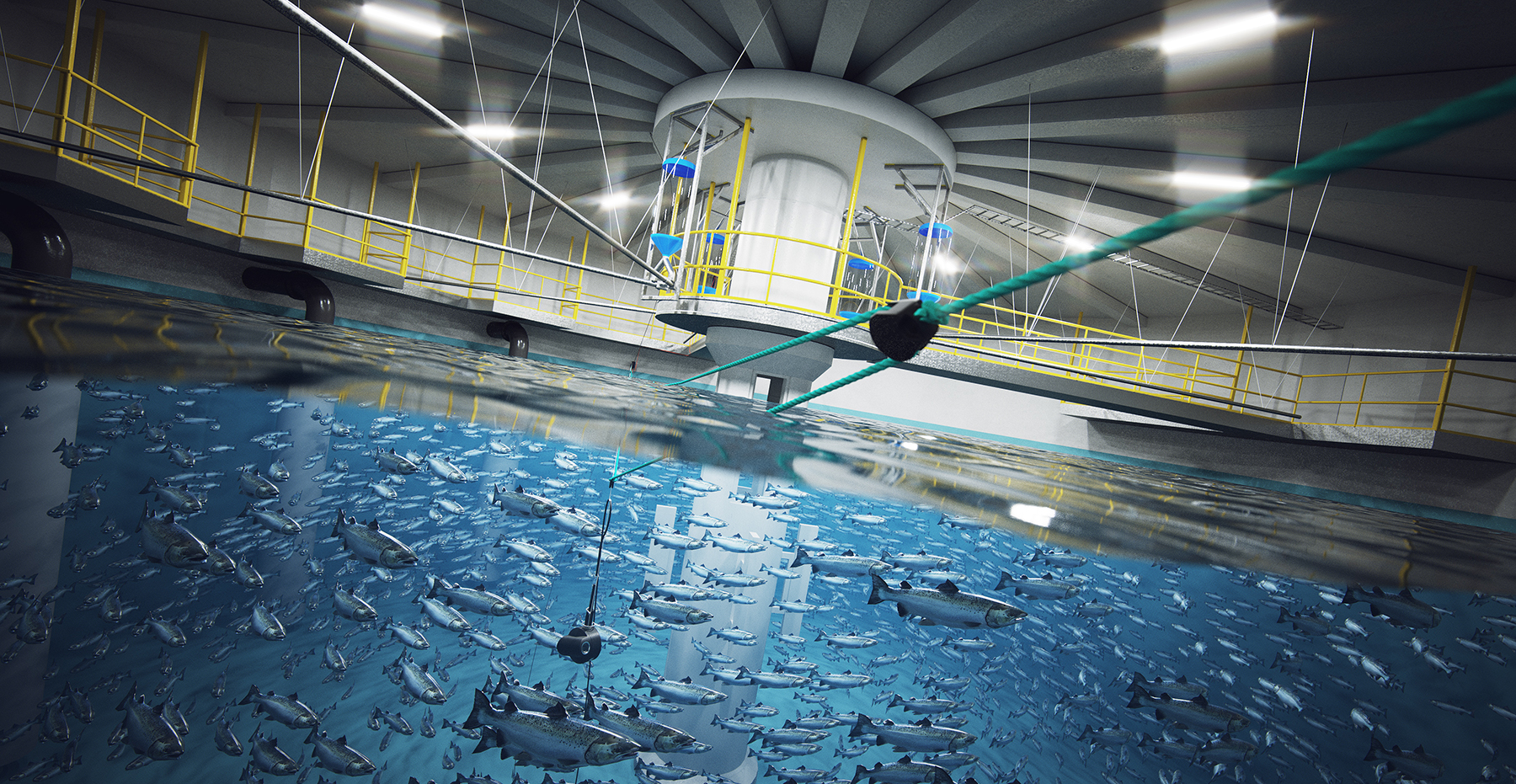

Fish escape has consequences for resource utilization, economy, and affects the industry’s reputation. Holes in the net account for 76 percent of escaped salmon and rainbow trout annually, making it the most common cause of fish escape, according to forskning.no. Other causes of escape include submerged nets, leakage from tanks, and transportation.

CleanPump prevents the most common cause of escapes in pens, which is holes in the net. With CleanPump, there’s no permanent installation in the pen. The pump is lowered when in use and raised when not in use. All components that are lowered into the net have rounded corners, ensuring that the pump won’t create holes in the net.

Several hours saved on mortality handling

Traditionally, manual dead fish handling is time-consuming. CleanPump offers an efficient and automatic solution that pumps the dead fish out of the pen using a pump.

One of the biggest advantages is that the pump can effectively be moved from pen to pen. This means that if you have a fish farming facility with, for example, 6–12 pens, you only need one pump to service them. This is possible because the pump isn’t permanently installed in the pen but is installed on the facility’s boat.

The total cost of using CleanPump becomes lower because it can be used on multiple pens, simplifies lice treatment, enables efficient deployment of the dead fish hose, reduces escape risk, and is plug-and-play on most boats.

Preparation for activities like lice treatment becomes easier since there’s no fixed object installed in the pen. This reduces the time operators spend on each pen, as they don’t have to remove objects from the bottom of the net before delousing vessels arrive.

Health and safety-friendly

When handling CleanPump, there are no heavy lifts, and one operator has control over the entire process. When multiple individuals operate a machine, communication issues often contribute to unwanted incidents.