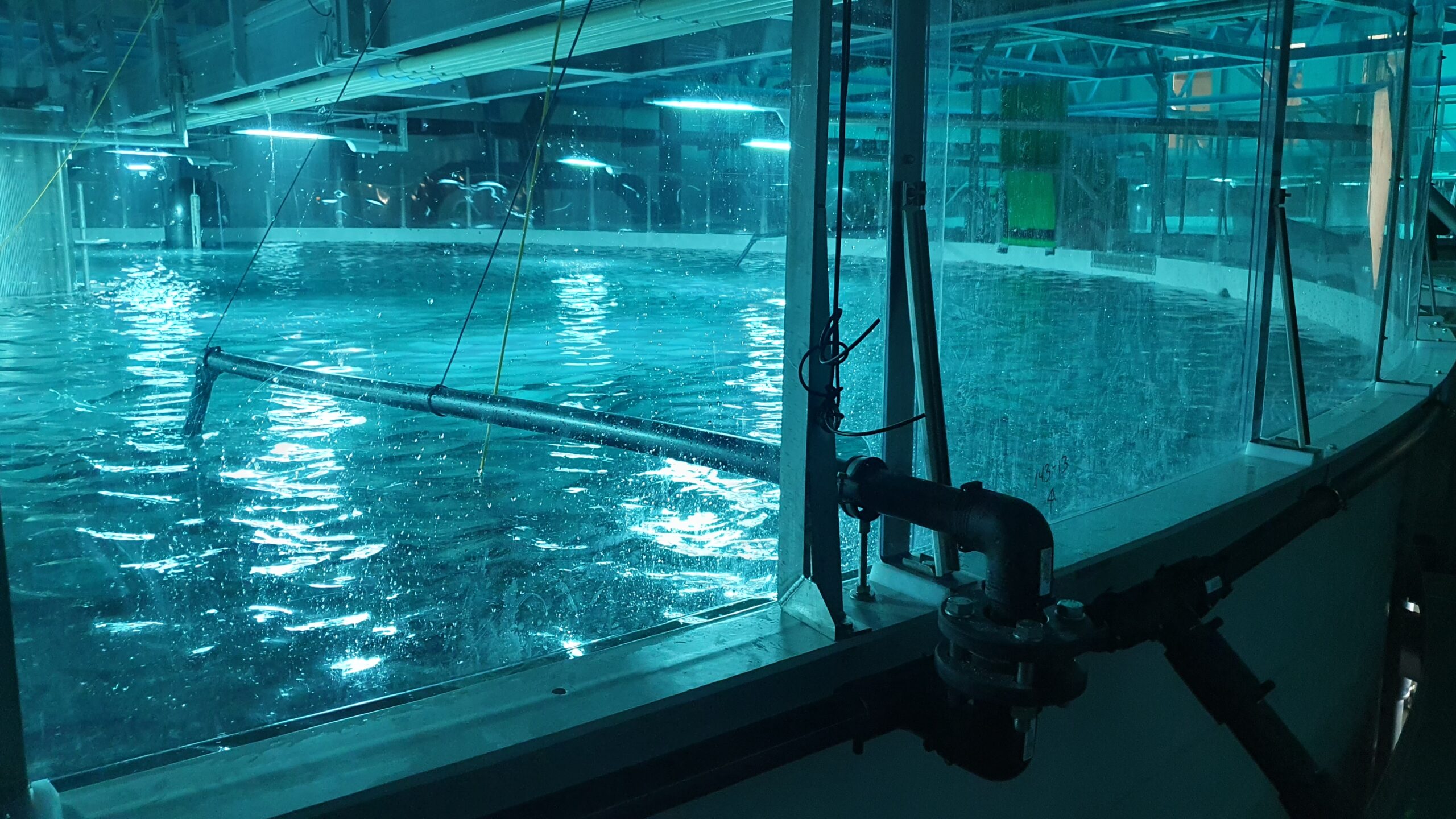

At the end of January, 200,000 fish were transferred to the tanks at Hofseth Aqua’s new postsmolt plant, where the fish will grow strong and reach a weight of up to 1 kg before being transferred to sea cages. Water feeding is among the newest of the many technologies we supply to land-based aquaculture, and Hofseth Aqua is the very first company to use this innovation.

A few months after the new technology’s introduction, Growth Manager Ingvild Holm of Hofseth Aqua can already report a number of positive observations.

‘When I see how the trout behaves with water feeding in the tank, I see a clear improvement in fish health. The fish are less stressed, and we know that less stress means better feed uptake and feed utilisation.’

‘We can now distribute a large quantity of feed at certain times of the day – what we call meal feeding. Continuous feeding throughout the day and night could result in only the biggest and strongest fish being able to access feed, which will create more runts in the tanks. Water feeding imposes virtually no restrictions – we can distribute a very large quantity of feed per minute.’

‘The fish are also prepared to feed better when they are placed in sea cages.’

Already seeing many benefits

So far, Ingvild and her colleagues have worked on adapting the feeding points to optimise feed spread.

‘We’re going from four to six outlets to improve spatial distribution in the tanks. Even before we’ve finished optimising the feed spread in the tank, we see that water feeding has far more and greater advantages than air feeding,’ she explains.

The spread is particularly important in trout farming.

‘With air feeding, the fish are aggressive at the surface – they fight over the feed. When feed is delivered underwater, the fish are calmer, stop fighting the other fish and eat more.’

‘We have not collected sufficient data to draw conclusions yet, but it appears that the fish are closer to their expected growth rate now than in the old plant that had air feeding,’ she explains.

Water feeding brings several advantages:

- Underwater feeding option – with feeding in multiple places and at multiple depths

- High capacity, meaning that the fish can access large quantities of feed when they have a strong appetite

- Gentle feed handling – using water to transport the feed reduces feed crush and pellet waste

- Low energy consumption compared with air feeding systems

- Strong reduction in microplastic

Large volumes planned for 2023

Another four postsmolt tanks will be put into operation in the near future, and Hofseth Aqua plans to deliver three million trout in 2023, most of which will have come through the postsmolt facility with water feeding.

‘It’s only when all six tanks are fully operational that we can really evaluate how successful this has been for us, but the results are very promising so far,’ she explains.

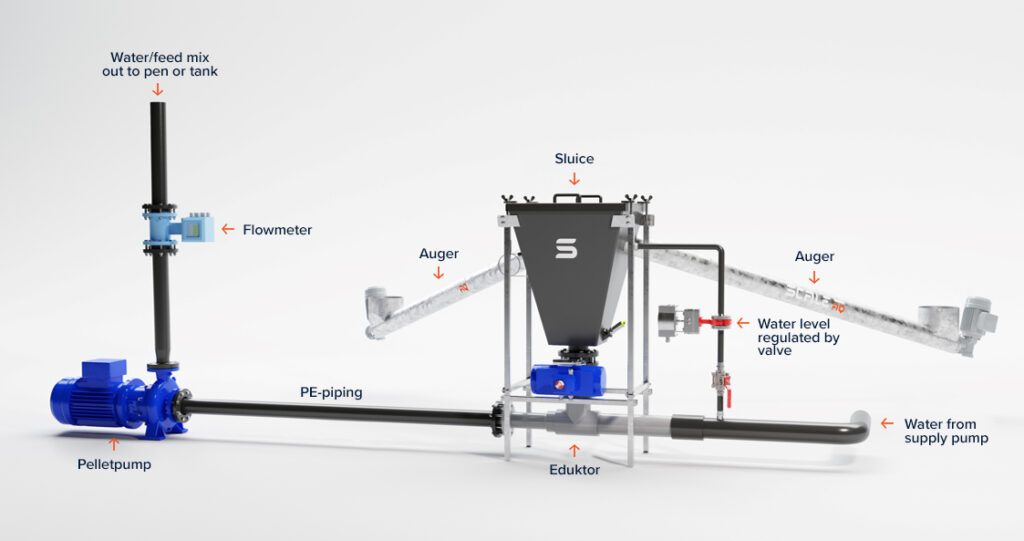

ScaleAQ’s water feeding technology is delivered with the FeedStation software, which has both a hypermodern user interface and open APIs for exchanging data with other systems. The software allows Hofseth Aqua to control operations as well as access data they need in their continuous work to improve fish welfare.

Helland Silosystem has also been involved in the delivery, as it has supplied the reception silo on the quay, conveyor to the storage silos and storage silos for the plant. Helland Silosystem’s long-standing experience of similar deliveries has helped to ensure the best possible handling of the feed before it is fed to the fish.

Low-maintenance and low power consumption

ScaleAQ is very satisfied with its successful cooperation with Hofseth Aqua and is assisting the company in its optimisation of the plant to ensure the best possible feeding and fish health.

Astrid Buran Holan is ScaleAQ’s Head of Welfare. She can tell us that the technology used in Hofseth’s postsmolt plant is very similar to the technology ScaleAQ supplies to sea-based aquaculture.

‘The actual system design is not particularly complicated, and it’s adapted to the different facilities we supply it to. A simple design means simple maintenance. The fact that the method is energy-efficient is also an important factor when the customers opt for water feeding,’ Astrid explains.

Read more about water feeding on our product pages.

You can also see our water feeding system in practice at Skansen in Trondheim during the Aqua Nor 2023 conference.