ScaleAQ has been supplying systems for handling dead fish since 1992. The systems can be supplied as standard models or customized according to the customer’s needs.

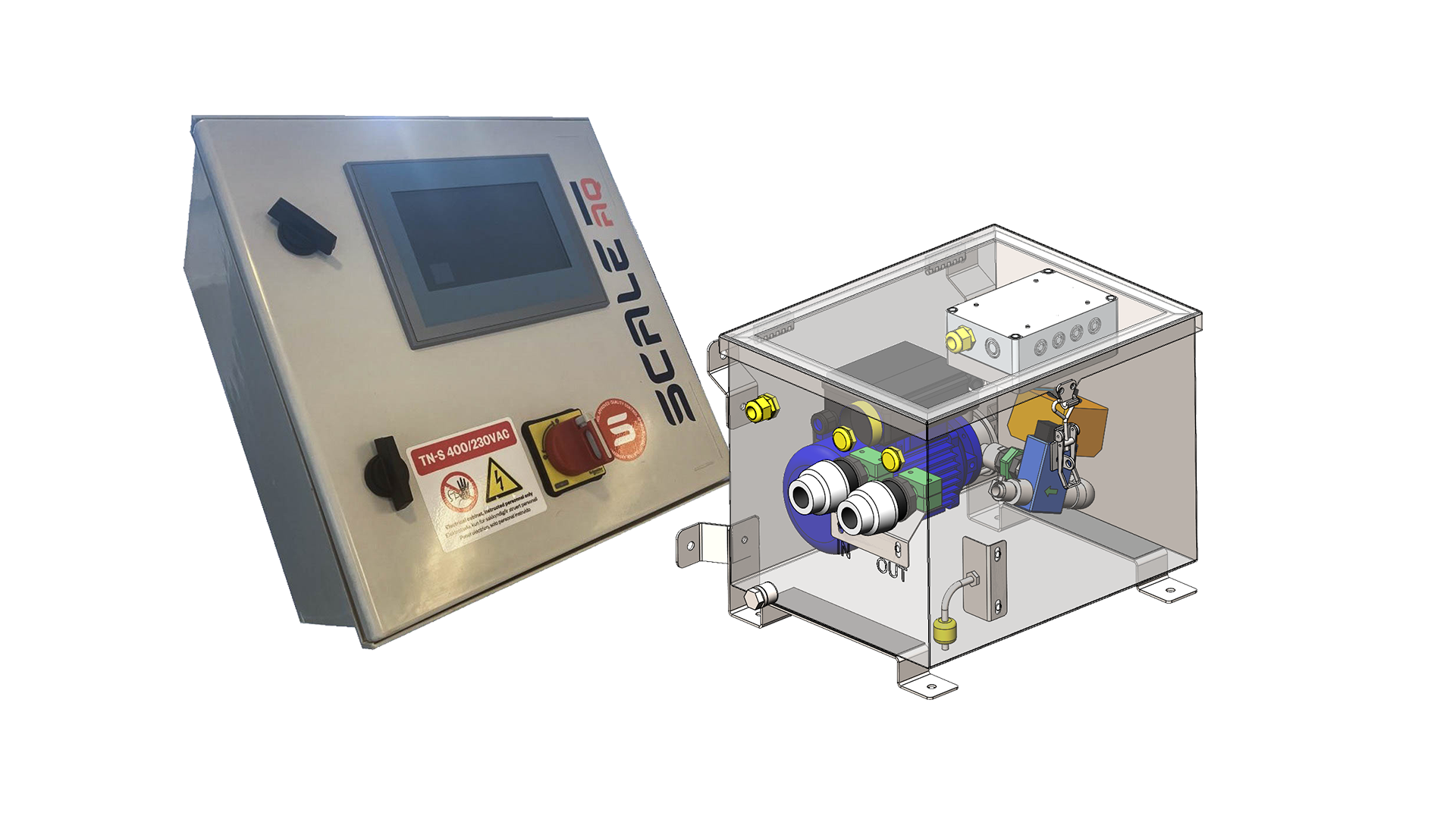

Grinding pump

- Hygienic and efficient ensiling system

- High levels of reliability and service life

- Standard tanks, as well as modular customizations

The submerged grinding pump is the most commonly used pump in ScaleAQ’s grinding tanks.

The cutting system on the pump consists of specially hardened impeller and cutting/bottom plates. The cutting plate has 8 cutting pockets that act as blades. When recirculating in the ‘day tank’, the waste/fish will compact.

The cutting rate reaches a rate of 8000 cuts per minute. The pump operates at a relatively low speed while offering powerful torque. The impeller is designed with a screw end that draws the waste into the pump. A standard 13.5 kW submerged grinding pump has a capacity of 52 l/second.

In the event of any blockage/wedging during the grinding process, it is possible to reverse the pump by using the reverse switch in the control cabinet. This will efficiently dissolve blockages.

We also supply a range of dry-facing grinding pumps with a wide range of capacities.

Please get in touch for a non-binding conversation on handling dead fish. We have a variety of standard tanks, but we are always happy to assist with customizations.