ScaleAQ has created its first ever climate balance sheet. It tells us what impact different activities within the business have on the climate, making it clearer where the implementation of measures can be most effective.

One of the UN Sustainable Development Goals that we are particularly focused on is is goal no. 13 (take urgent action to combat climate change and its impacts), which is why we are working with a long-term focus to reduce the carbon and environmental footprint of our own value chain, and we offer solutions and technology that reduce our customers’ impact on the climate

Biggest emissions come from purchases

We have used the model developed by Klimakost in Norway to prepare ScaleAQ’s first ever climate balance sheet. In the first instance, our analysis covers only the Norwegian arm of the company. This model allows us to map:

- greenhouse gas emissions emitted directly from the company

- indirect emissions from purchased energy used by the company

- indirect emissions from input factors such as purchased products and services.

ScaleAQ’s climate balance sheet tells us that the biggest source of greenhouse gas emissions – by some margin – is our purchases. Around 80 per cent of ScaleAQ’s greenhouse gas emissions come from the purchase of goods, and plastic and steel products represent the vast majority of these emissions, totalling 87%.

Where can we cut emissions?

The UN Sustainable Development Goals are not just commitments we have signed up to – we actually prefer to regard them as offering us a sea of opportunity. There is much we can do to reduce our greenhouse gas emissions.

For example, a greater element of renewable energy in the supply chains for plastic and steel products is just one such opportunity. Climate-friendly raw materials throughout our supply chains are another such opportunity. One example of this is plastic, which we use extensively in aquaculture. At present, plastic is manufactured almost exclusively using fossil-fuel-based raw materials, but there are new types of plastic available that are based on renewable, non-fossil-fuel-based raw materials.

There is no difference in quality or lead time for these products, but plastic products made with certified and renewable inputs continue to be more costly. However, there are grounds to believe that the price of what is known as ‘green plastic’ will decrease as the market matures and volumes increase – new products and technologies have made this journey before.

You can read more about this on the pipe blog published by our supplier Hallingplast.

A third opportunity to reduce our carbon footprint is to reduce energy consumption within the business. One of ScaleAQ’s contributions in this regard is the heat exchange plant operating at our Frøya production facility. This uses seawater as a heat source and warms up our buildings while also providing us with hot water.

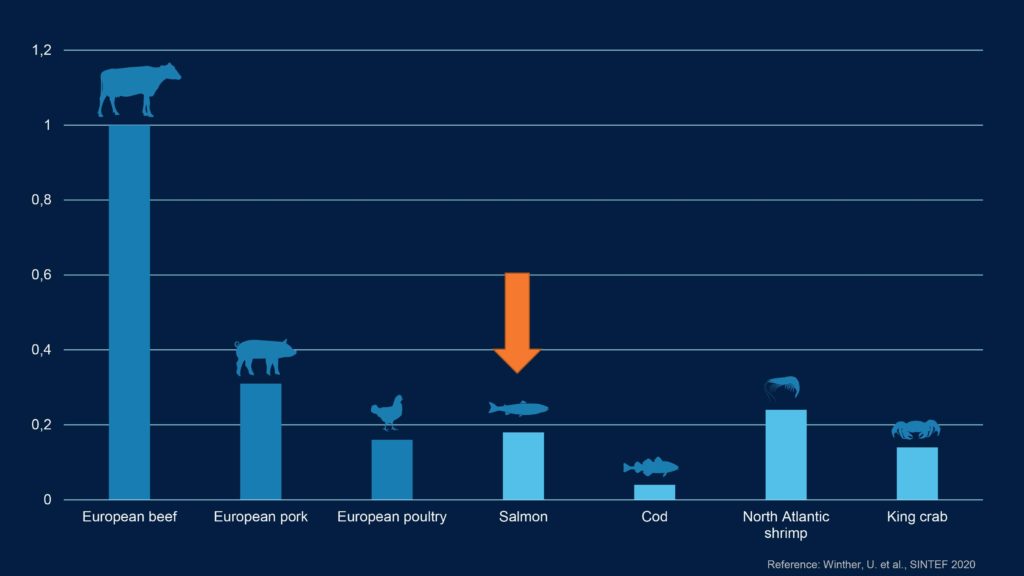

Seafood has a low climate footprint

Innovation is a key factor

At ScaleAQ, we believe that innovation is at the heart of fulfilling the UN’s Sustainable Development Goal no. 13. We will be a driving force in achieving this goal by means of technological development and an active commitment to sustainability in aquaculture.

The climate balance sheet for the entire aquaculture industry shows that fish feed is the industry’s largest source of greenhouse gas emissions as a whole[1]. Technology that improves feed factor, reduces feed loss, optimises growth and reduces mortality will be critical and the most effective way of reducing the carbon footprint of aquaculture. Here we are likely to see the recently launched smart feed spreader (SmartSpreader™) contribute to these efforts by helping to spread feed further and distribute it better in the cage.

Electrification is another good example. ABB & Bellona have calculated that the greenhouse gas emissions from Norwegian salmon farming can be reduced by 75 per cent through the electrification of the industry – and that is using technology available today[2]. It may be possible to cut carbon emissions even further with the advent of new technology.

Those of us who supply equipment to the aquaculture industry must be active participants in this technological shift by showing buyers where the opportunities for cutting emissions are greatest and by facilitating electrification.

ScaleAQ and its subsidiary Moen Marin now offer hybrid facilities and wholly-electrical solutions for both feeding barges and service vessels, delivering up to a 60 per cent reduction in fuel consumption. It can be guaranteed that new and even more efficient products are on the horizon.

Low can go lower

At ScaleAQ, we choose to be optimists. We must believe in the future and the opportunities that will be provided to us by research and new technology. While remaining committed to sustainability, we must hold two ideas in our heads at once: Seafood already has a low carbon footprint compared to the production of other animal proteins. Nevertheless, we can work together to make this footprint even smaller.